Attempts to strengthen the education of health professionals in Southern Africa has now bore fruit in Namibia, with the first 3D printed anatomical models created at UNAM’s Hage Geingob Campus, in Windhoek.

This was made possible with the generous support of European Union Erasmus Plus project and funding from the DarisanaPlus grant. UNAM is part of a large partnership which consists of Welwitchia Health Training Centre, WITS University, Sefako Makgatho University and the University of Pretoria, along with European partners – University of Turku, Maastricht University and University College Dublin.

The collaboration aims to use 3D printing technology to support health education through printing of educational models and contributing to research projects. The broader objective of this project is to back staff development; collaboration on teaching, learning and assessment practices; creation of recommendations for integrated blended learning, and research.

The current scarcity of human tissue for student dissection and research, compounded by COVID–19 and the deficiencies within the Anatomical Donations and Post-Mortem Examinations Ordinance 12 of 1977, meant that other resources for student learning had to be found.

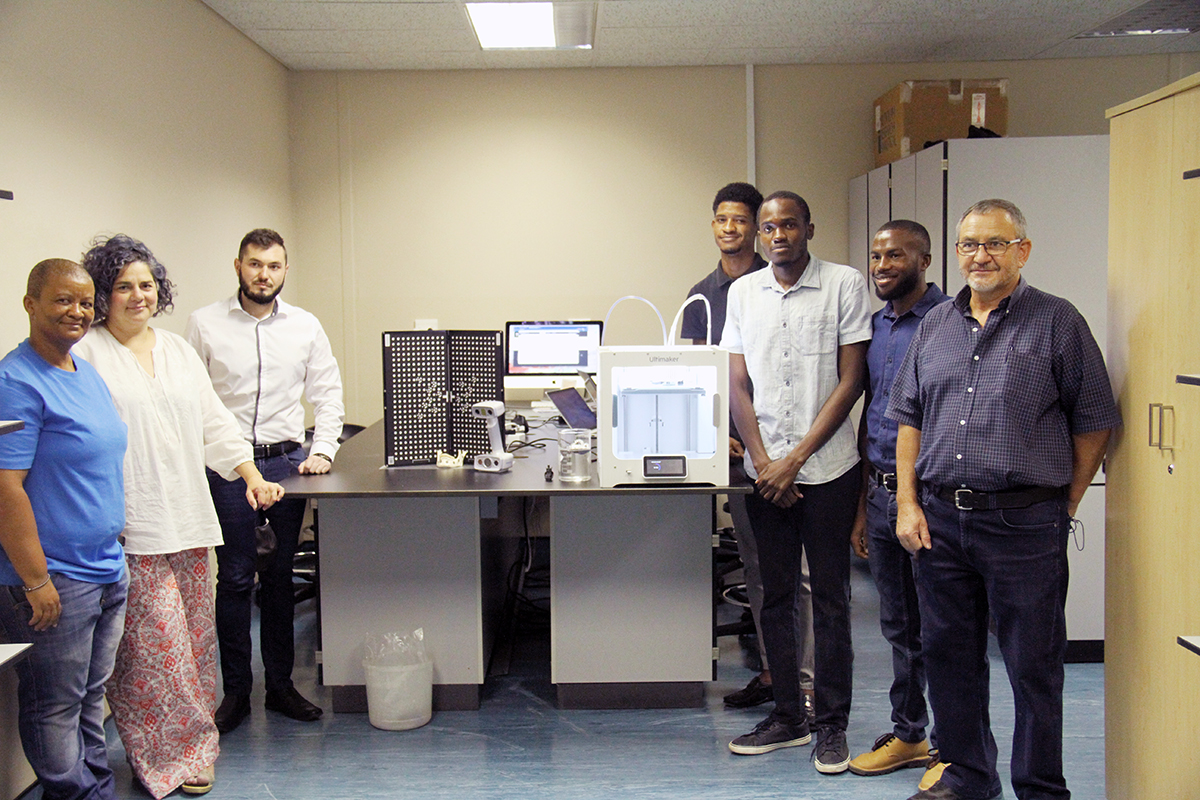

Lecturer for Human, Biological and Translational Medical Sciences, Dr Adéle Du Plessis, explained that the project has been in motion since 2019 when the application was made and eventually granted in late 2020, and finally took off in 2021.

“The aim for UNAM is to start small and ensure that we have enough competent staff who can use this technology. Thereafter, explore more options other than improved teaching,” remarked Dr Du Plessis. This, however, was not the first department to use 3D printed technology. The Dirisana+ project was the first to do so – specifically to improve the training of health students in using 3D printed anatomical models.

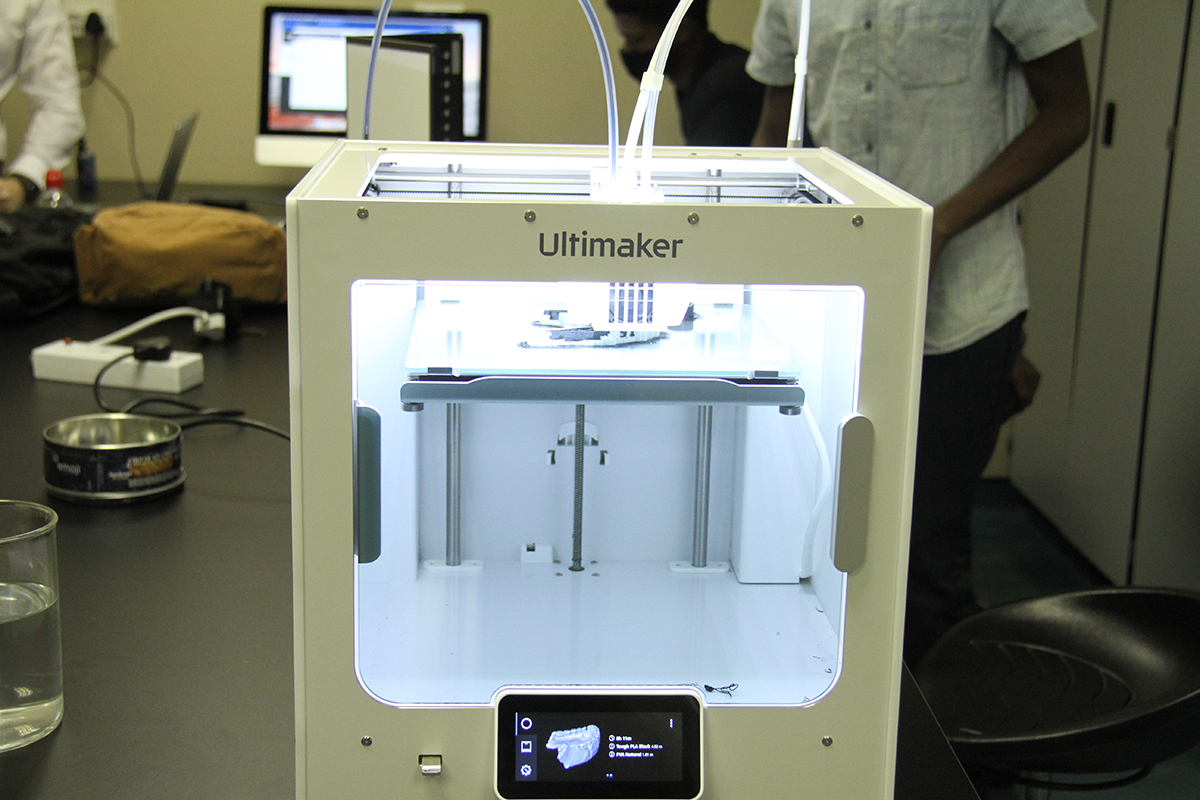

Earlier this year, in January, training of various technicians from partnering institutions took place at the Hage Geingob Campus with different models being successfully printed. The trainees were from Welwitschia Health Training Centre and UNAM. Training was conducted by Mr. Hendrik Swart from BuildVolume, a 3D printing company. According to Swarts, the technicians were trained to use a 3D printing technology known as fused deposition modeling, more commonly known as FDM.

This type of 3D printing process is one that uses a continuous filament made of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited onto the growing work. The print head is moved under computer control to define the printed shape. Usually, the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The institution is really excited to embark on this new endeavor and possibilities.